Krofta Multifloat DAF

The ultra-compact DAF

Compact, versatile and flexible.

The Krofta Multifloat rectangular design combines flexibility with high performance, making it the ideal choice for facilities with space constraints.

Available in both vertical (MFV) and horizontal (MFH) configuration, the Multifloat ensures seamless integration into any plant layout.

Whether you need an industrial or municipal application, the Multifloat delivers high-capacity treatment with compact efficiency.

Adaptable solutions for any space

- Customizable Configurations: Vertical or horizontal installations to fit available space.

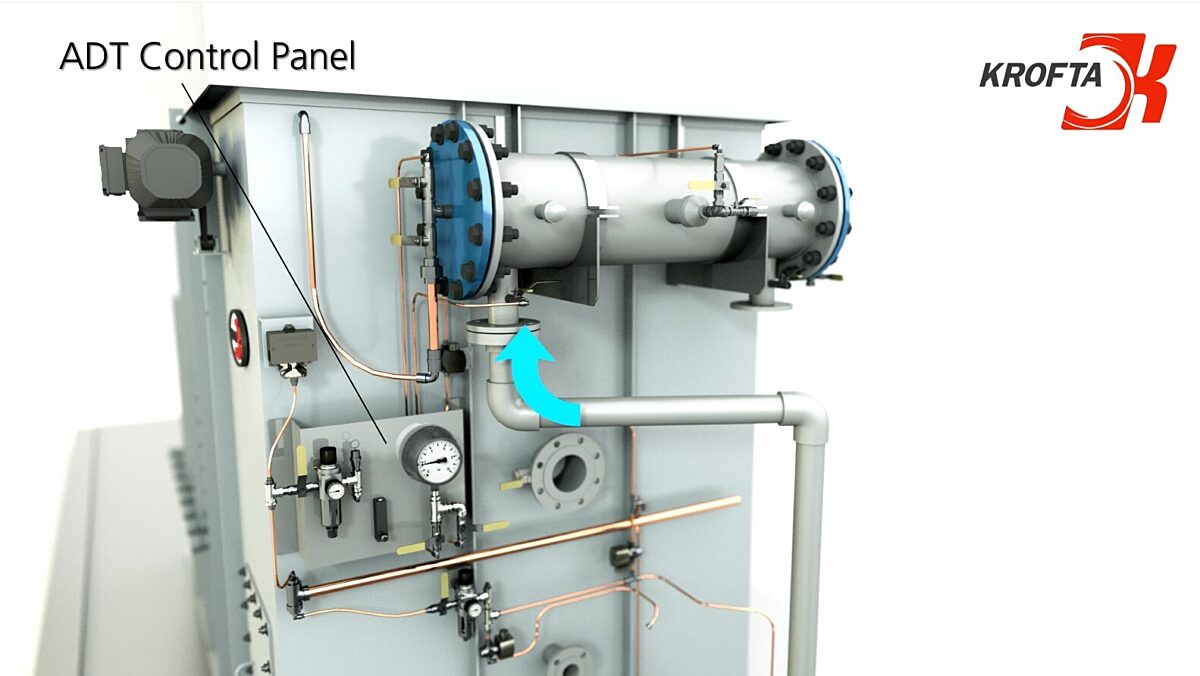

- Patented ADT: Maximizes flotation efficiency with microbubble technology.

- Durable Construction: Stainless steel components for longevity and reduced maintenance.

- Krofta Cockpit: IoT-enabled for real-time monitoring and optimization.

- Wide Capacity Range: Handles flows from 50 to 1,500 GPM, making it suitable for operations of varying sizes.

- Rental Options: Short-term solutions to meet temporary increases in demand, infrastructure upgrades, or urgent equipment replacements.

Flow Enhancement Cells for larger flotation area.

The Multifloat employs an advanced DAF process to ensure optimal solid separation and water clarity. Here's how it works:

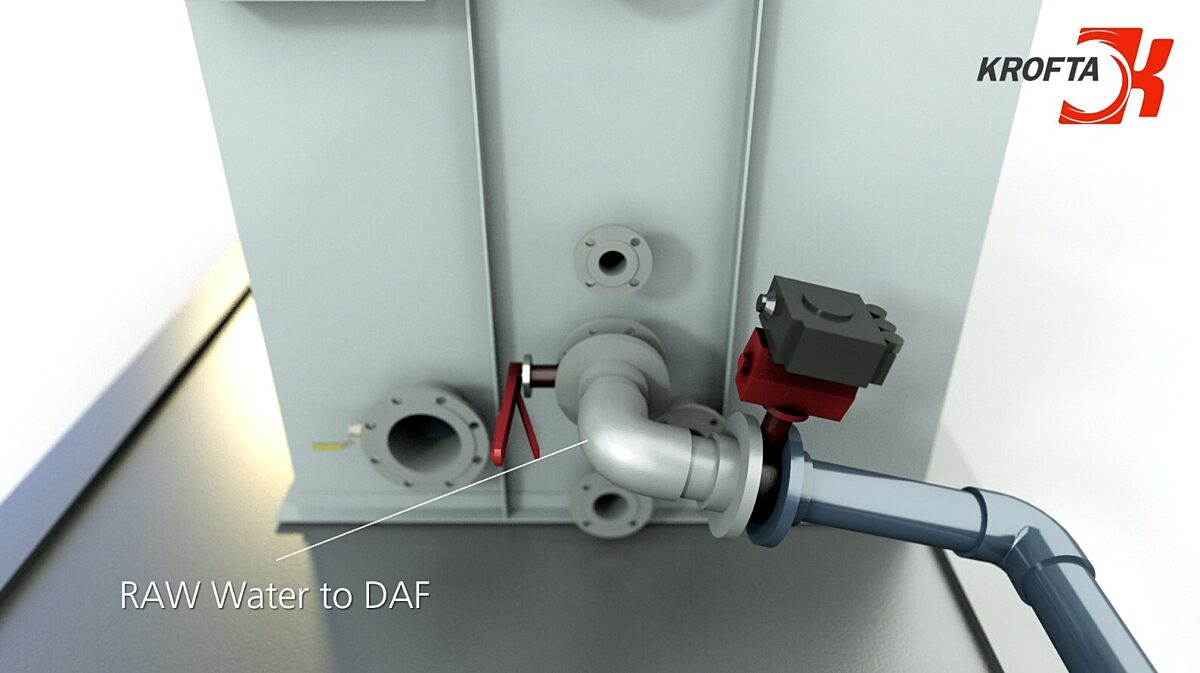

- Aerated Flow Introduction: Raw wastewater is mixed with aerated recycle flow from the patented Air Dissolving Tube (ADT).

- Flotation Zone: Flocculated particles attach to micro-bubbles, generated by the ADT, and rise to the surface within the flotation tank.

- Effluent Separation: The use of proprietary Flow Enhancement Cells - FEC's, enlarging the flotation area, results in an efficient and highly compact DAF system. The clarified water flows through strategically designed extraction points, while floated solids are directed toward the sludge collection mechanism.

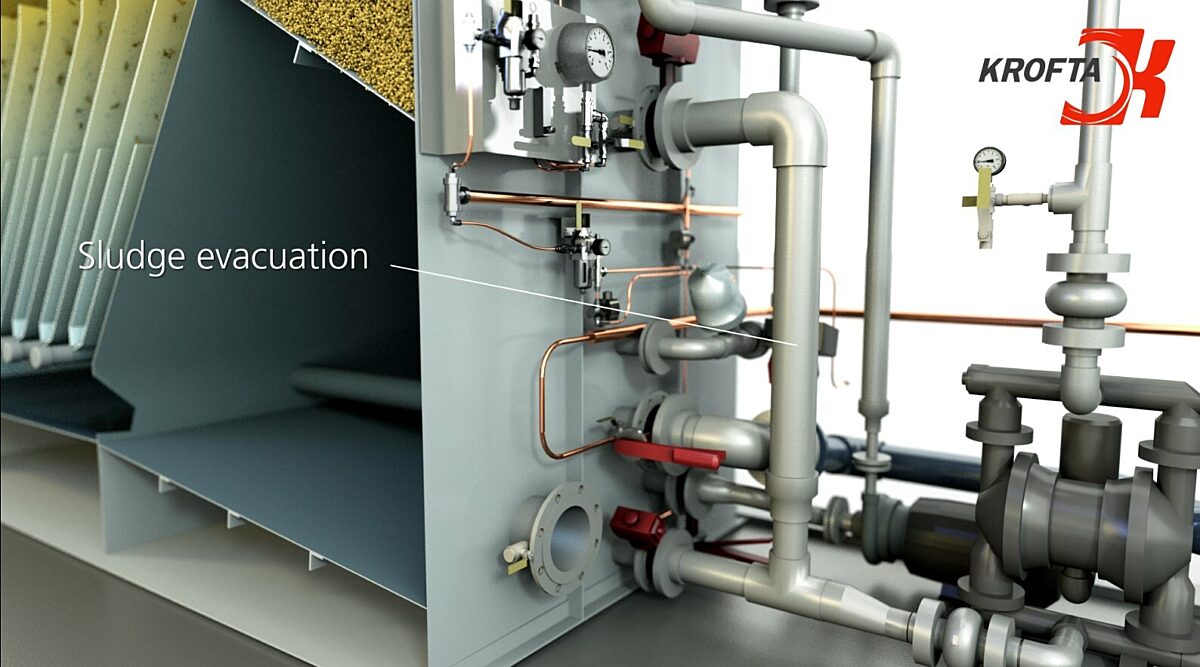

- Sludge Removal: A rake assembly pushes floated materials into a hopper for collection and subsequent disposal or treatment.

- Grit removal: Grit or other sediment are collected in the bottom of the unit and purged by an automatic valve.

- Sludge Blanket Controller: Precise water levels are maintained via an advanced level control system, ensuring consistent operation and superior sludge removal.

- Pretreatment: Depending on the effluent quality requirements, the system may be operated with or without chemical pre-treatment for coagulation and flocculation. The KroftaCare chemicals are specifically designed to enhance the performance of Krofta DAF systems by optimizing solid separation at minimal operational costs.

Operational Advantages Krofta MultiFloat

- Compact Footprint: Optimized for tight spaces without sacrificing performance.

- Cost-Effective: Energy-efficient design (ADT-tube technology) reduces operational expenses.

- Low chemical consumption: Maximum removal efficiency due to Flow Enhancement Cells (FEC's)

- Low Maintenance: Fewer moving parts minimize downtime and repair costs.

- Safe Operation: Viewing windows and accessible components make monitoring and maintenance simple and safe.

- Sludge Blanket Controller: This feature ensures precise sludge removal and consistent tank levels, improving overall process efficiency and reducing operator intervention.

- Krofta Cockpit: IoT-enabled for real-time monitoring and optimization.

Rent a Krofta DAF Multifloat

Ready to revolutionize your wastewater treatment process? Contact us today to try or rent a Krofta DAF Multifloat system.

- Krofta DAF Multifloat technology assessment

- Plant expansion

- Planned maintenance

- Emergency intervention

- Medium and Long Term renting solutions

Start Krofting. Contact us today.

Need a Krofta DAF? We are looking forward to sharing insights on the most efficient solution for your liquid-solid separation challenge.