Krofta Air Dissolving Tube

Best-in-class flotation with proprietary micro-bubble technology

Faster Air dissolution, lower retention time

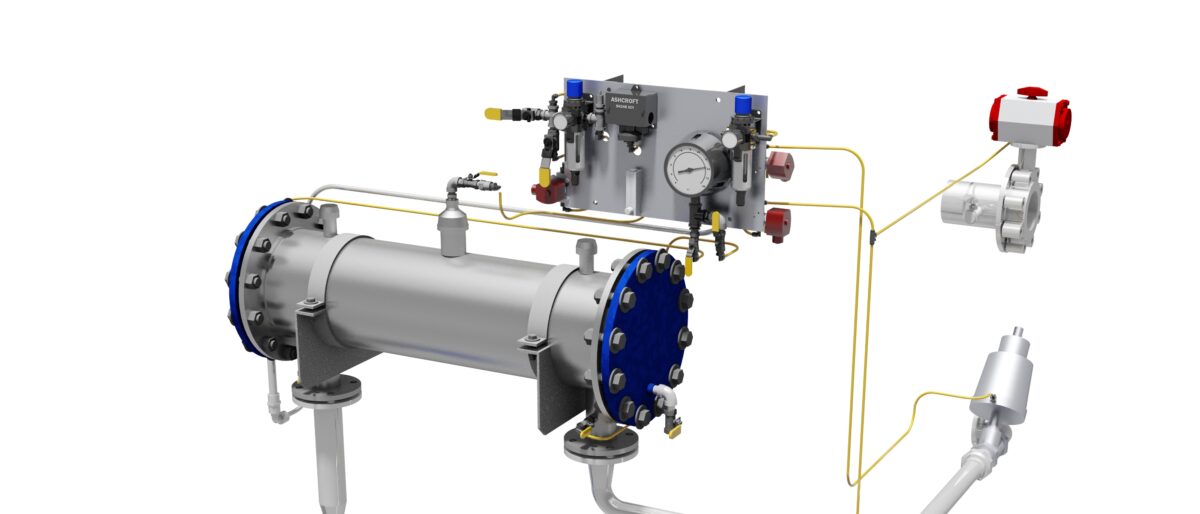

The Krofta Air Dissolving Tube (ADT) is the technological heart of every Krofta DAF system. Pioneered by Dr. Milos Krofta, the ADT revolutionized DAF technology by replacing traditional, bulky pressure vessels.

This compact yet powerful innovation offers faster air dissolution, reduced maintenance, and a smaller system footprint. Since its inception in the 1970s, the ADT has been a critical component in thousands of installations worldwide, earning its reputation as a trusted cornerstone of efficient water treatment.

Why the ADT Stands Out

- Exceptional Efficiency: The ADT dissolves air into water in just 8-12 seconds, a fraction of the time required by traditional pressure vessels.

- Space-Saving Design: Smaller and lighter than conventional systems, the ADT optimizes plant floor space.

- Low Maintenance: With no moving parts and a robust stainless steel construction, the ADT minimizes downtime and ensures longevity.

- Customizable and Adaptable: Easily retrofitted to existing DAF systems, the ADT meets diverse wastewater treatment requirements with precision.

How the Krofta ADT works

The ADT employs a combination of centrifugal force and advanced air dispersion technology to create microbubbles that facilitate superior flotation. Air is released across a proprietary air panel within the tube, generating uniform bubbles between 10-70 microns. These bubbles adhere to suspended solids, lifting them to the surface for removal. The vortex flow within the tube eliminates undissolved air, ensuring reliable and efficient performance.

- Microbubble Technology: The ADT produces microbubbles ideally suited for separating solids from wastewater. This ensures maximum flotation efficiency and superior water clarity.

- Advanced Flow Design: The vortex flow pattern eliminates excess undissolved air, preventing issues like water hammer or turbulence, which can reduce treatment effectiveness.

- Adaptable Nozzles: A specially designed inlet nozzle enables the ADT to accommodate varying waste streams, making it a versatile choice for industrial and municipal applications.

Highest efficiency. Lowest opex.

- Compact Efficiency: The ADT is six to nine times smaller than traditional pressure vessels, significantly reducing footprint requirements.

- Cost Savings: Reduced air and water consumption translates to lower operational expenses.

- Sustainability: By optimizing chemical and energy use, the ADT supports environmentally responsible operations.

A Future-Proof Solution

The ADT not only addresses today’s wastewater challenges but is designed to evolve with future demands. Its robust and modular design ensures seamless integration into existing systems, while its adaptability allows it to meet changing regulations and treatment requirements.

Krofta DAF. ADT inside.

The Krofta Advanced Dissolved Air Flotation (ADT) system powers the three flagship Krofta DAF technologies, each designed to address specific water treatment needs with unparalleled efficiency and sustainability:

- Krofta Multifloat: A versatile DAF system ideal for applications requiring high solids separation and sludge thickening, delivering superior performance in compact footprints.

- Krofta Supracell: The high-flow DAF solution designed for rapid clarification and recovery, offering unmatched efficiency and reduced chemical consumption for industrial applications.

- Krofta Sandfloat: Combines DAF technology with sand filtration for enhanced removal of fine particles and polishing of treated water, ensuring top-quality effluent.

These systems, driven by ADT technology, provide industry-leading solutions tailored to meet diverse water treatment challenges.

The ADT tube makes separation faster, cleaner, and more reliable.

Why is the Krofta Air Dissolving Tube superion to conventional air saturation solution in a DAF?

1. Working Mechanism of Air Dissolving Tube (ADT)

The ADT provides a specially designed tube in which air is injected into pressurised water under controlled conditions, generating micro-bubbles.Water enters through a nozzle, creating a tangential/spiral flow inside the tube. Air is introduced via porous panels (or membranes) and mixes with the water under pressure.

The design allows quick saturation (retention times on the order of 8–12 seconds) compared to typical large pressure vessels.

After saturation, the aerated (air-saturated) water is released into the flotation zone of the DAF system, the pressure is dropped and micro‐bubbles form, attach to solids, and carry them to the surface.

2. Key Advantages of the Krofta ADT

High micro-bubble generation efficiency

The ADT’s design (panel + spiral flow + bleed off of excess air) ensures fine bubbles are produced, increasing bubble‐solid contact, which enhances flotation efficiency.

The higher the microbubble count / smaller the bubble size, the better the attachment to suspended solids and the higher the flotation yield.

Reduced air & energy consumption

Because the ADT achieves effective saturation with less air and in shorter time, it reduces energy (for air compression) and pump size/recirculation requirements.

Compact sizing / footprint benefi

The ADT is much smaller than traditional pressure saturation vessels (six to nine times smaller by volume in one specification) which lowers footprint and civil/structural cost.

Smaller equipment means easier installation, retrofit, and potentially lower CAPEX.

Improved separation performance

Because the ADT produces a more uniform and controlled bubble field, the DAF system can achieve better suspended solids / TSS removal (some data suggest improvement of ~10% or more) when retrofitted.

The better and more uniform bubble attachment means smaller flocs (or lighter particles) can be floated that might otherwise escape in less optimised systems.

Retrofit friendly and versatile

The ADT can often be retrofitted into existing DAF installations (vessel, unit) to upgrade performance without replacing the whole system.

Various sizes accommodate different flows and system configurations.

Simplified operation and maintenance

Fewer moving parts (no large jets/saturators), simpler internals, less risk of entrained large bubbles or tanking issues.

Because of the bleed‐off and internal flow control, the chance of undissolved air being carried into the flotation zone (which can cause turbulence and reduce efficiency) is lower

Can I integrate or retrofit my DAF design with a Krofta ADT?

When you consider using the Krofta ADT (or comparing it to alternatives) in your design or retrofit, here are questions and checks you should make:

1. What is the flow rate through the ADT and the required air saturation rate? Does the ADT match your application (industrial effluent, TSS load, oil & grease, etc.)?

2. What is the operating pressure for the ADT? Ensure it’s reasonable (many sources say ~65-85 psi / ~4.5-6 bar) compared to older large vessels.

3. What is the retention time inside the ADT? The shorter the better (8–12 seconds claimed) for efficiency.

4. What is the bubble size distribution resultant from the ADT? Smaller bubbles = more surface area = better floc attachment.

5. Can the ADT be retrofit into your existing DAF or will you need full replacement?

6. What is the expected energy consumption (air compressor + pump) and how does that compare vs alternative saturators?

7. What is the expectedchemical reduction (coagulant/flocculant) due to enhanced bubble performance?

8. Are there operational constraints (maintenance, cleaning of panels, bleed‐off management, etc.) that you should account for?

9. What is theslug load / TSS / oily solids load the system can handle and what is the actual demonstrated removal performance for your case?

10. Ensure the manufacturer provides performance data in similar industrial context (your effluent type, solids load etc.)

In short:

The Krofta ADT is “better” than many conventional air injection (or saturator) solutions because it:

-

Generates finer, more uniform micro-bubbles → better flotation efficiency.

-

Uses less compressed air and smaller recycle flows → lower energy and operating cost.

-

Has a much smaller footprint and can be more easily installed or retrofitted.

-

Improves TSS/solids removal performance, especially for challenging effluents.

-

Simplifies operation and improves reliability (less “undissolved air trouble”, less large bubble coalescence).

Start Krofting. Contact us today.

Need a Krofta DAF? We are looking forward to sharing insights on the most efficient solution for your liquid-solid separation challenge.